크린룸 시스템 크린룸 시스템

▶ 크린룸 설계

- 크린룸 설계의 유의점(Design Guileliness)

- 기류방식(Patterns of Air Flow)

층류식(수직.수평), 난류식, 혼류식, 터널식이 있고, 각각의 특징을 가지며, 사용목적을 고려하여 결정합니다.

- 청정도(Cleanliness Level)

크린룸의 청정도는 제품에 요구되는 정도에 의해 결정됩니다. 청정도 레벨은 기류방식, 환기횟수, 실내압력 등을 충분히 검토함으로써 달성됩니다.

- 계획(Lay-Out)

작업성을 고려하여 청정도를 만족하도록 Layout을 결정합니다. 먼지 발생이 많은 작업은 다른 작업과 격리합니다. 또 사람, 물건의 출입구, 통로 UTILITY, 유지보수등을 종합적으로 검토하는 것이 필요합니다.

- 구조, 재료(Structure & Materials)

가능한 한 실내 표면을 매끄럽게 해서 기류가 흐트러지거나 먼지가 쌓이지 않는 구조로 합니다.

먼지발생이 적을 뿐만 아니라 입자가 잘 부탁되지 않고 청소가 용이한 재료를 선택합니다.

작업내용에 따라 내약품성, 내습성, 내화성을 가진 재료를 사용하는 경우도 있습니다.

- 부속장치(Equipments)

크린룸을 구성하는 주변장치에는 먼지제어, 압력유지용에 AIR SHOWER(사람의 입출용), Pass Box(물건출입용), Safety Damper(실내압력조정용)등이 있고 물품, 포장들의 보관을 위한 클린 스토카, 클린락카 등이 있습니다.

따라서 각각 기능을 충분히 이해하지 않으면 안됩니다.

- 사람과 물건의 차이(Control of Working Persons and Materials)

작업자 외부에서 반입디는 물품은 최대의 발진원인입니다. 무진복과 화장의 문제 등을 포함하여 작업자는 크린룸화에 대한 기본지식이 필요합니다.

- 유틸리티(Utility)

급배수, 가스, 전기 등 에너지공급을 위한 장치는 기류방식, Layout의 Flexibility를 고려하여 결정하여야 합니다.

또 유지보수시에는 청정도 저하를 초래하지 않도록 주의할 필요가 있습니다.

- 안전대책과 비상설치(Safety & Emergency Plan)

크린룸은 밀폐구조이므로 화재, 가스누설 등에 대한 대책이 필요합니다. 또 정전에 의한 문제가 되는 장치는 비상전원설비를 갖추는 것을 검토할 필요가 있습니다.

Air-Llow

ITEMS |

수직층류방식

Vertical Laminar

Airflow Clean Room

|

수평층류방식

Horizontal Laminar

Airflow Clean Room

|

난류방식

Turbulent Airflow

Clean Room

|

클린튜브방식

Clean Tube

Clean Room

|

터널방식

Tunnel

Clean Room

|

| Cleanliness Level |

Class 1~100 |

Class 100 |

Class 1,000~100,000 |

Class 1 |

Class 1~100 |

Cleanliness Level

in operation |

작업자로부터

영향은 적다 |

상류발진이 하류에

영향을 미친다 |

작업자로부터

영향 있음 |

작업자로부터

영향 있음 |

작업자로부터

영향은 가장적다 |

| Initisl Cost |

High |

Middle |

Low |

Low |

Middle |

| Operating Cost |

High |

Middle |

Low |

Low |

Middle |

| Modification |

Easy |

Difficult |

Easy |

Difficult |

Difficult |

Maintenance of

Manufacturing

Machinery |

Easy |

Easy |

Easy |

Difficult |

Easy |

| Expansion |

Difficult |

Difficult |

Difficult but possible |

Difficult |

Easy |

| Air Handling whit Precise control |

실전체 제어를 위해 실내의 불균형 약간 있음 |

상류의 발진이 하류에 영향을 미친다 |

불균형 있음 |

고청장치 유지 |

작업부마다 고밀정도 제어 가능음 |

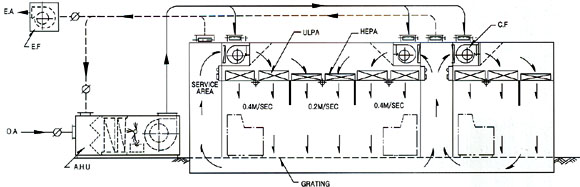

▶ CLEAN TUNNEL MODULE SYSTEM

- 반도체 정밀기기 공정 LINE에 적합한 SYSTEM이다.

- CLASS 1~100을 유지하며 작업공간과 통로의 ZONING 분리가 가능하다.

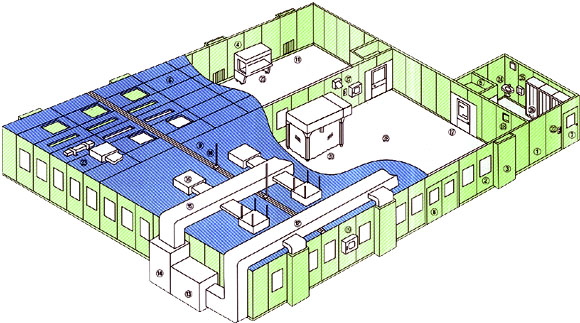

▶ 난류형 CLEAN ROOM의 모형도

(1) panel

(2) panel whit window

(3) panel whit dust-equipped

(4) panel whit wall outlet-equipped

(5) Transomed panel

(6) Ceiling panel

(7) Single-swing door

(8) Double-swing door

(9) Raceway

(10) Hanger

|

(11) Return grill

(12) Return dust

(13) Inermediate filter

(14) Air-conditioner

(15) Air supply dust

(16) Hepa box

(17) Air shower

(18) Postitive-pressure damper

(19) Pass box

(20) Clean booth

|

(21) Clean bench

(22) Lihting switches

(23) Fluorescent lamp

(24) Wash-stand

(25) Air towel

(26) Dressing lockers

(27) Intercom

(28) Floor

|

|